Project Description

Ultrasonic Electrochromic Glass Manufacturing Coatings

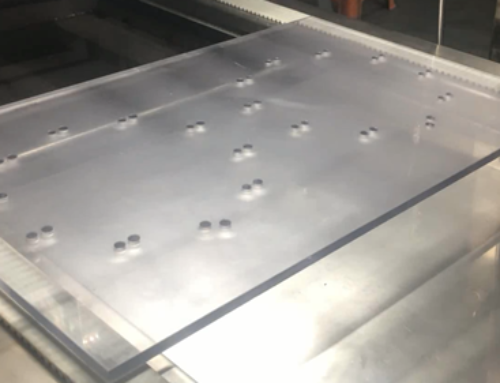

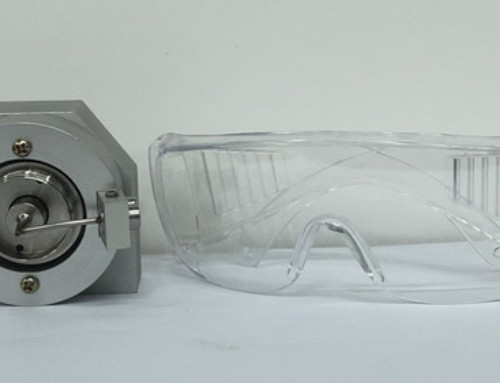

CHEERSONIC ultrasonic spraying equipment has been proven to be able to spray ITO and other chemicals, such as nano-solutions, in the manufacture of smart or electrochromic glass. With the continuous development of the energy-efficient glass market, CHEERSONIC ultrasound assists manufacturers in developing new coating processes. Ultrasonic nozzles eliminate the use of pressure to atomize liquids and evenly spray nanomaterials onto the glass without overspray or dripping. Ultrasonic spraying equipment has long life, repeated use, and no clogging.

Ultrasonic nozzle advantages:

• Environmentally friendly spray

• Material consumption reduced to 80%

• Uniform and stable spraying results

• Can spray nanomaterials

• Minimal maintenance and downtime

• Highly uniform nanofilm

• Precise, non-clogging ultrasonic spray technology is proven in solar glass manufacturing processes

• Precise control of coating thickness