Project Description

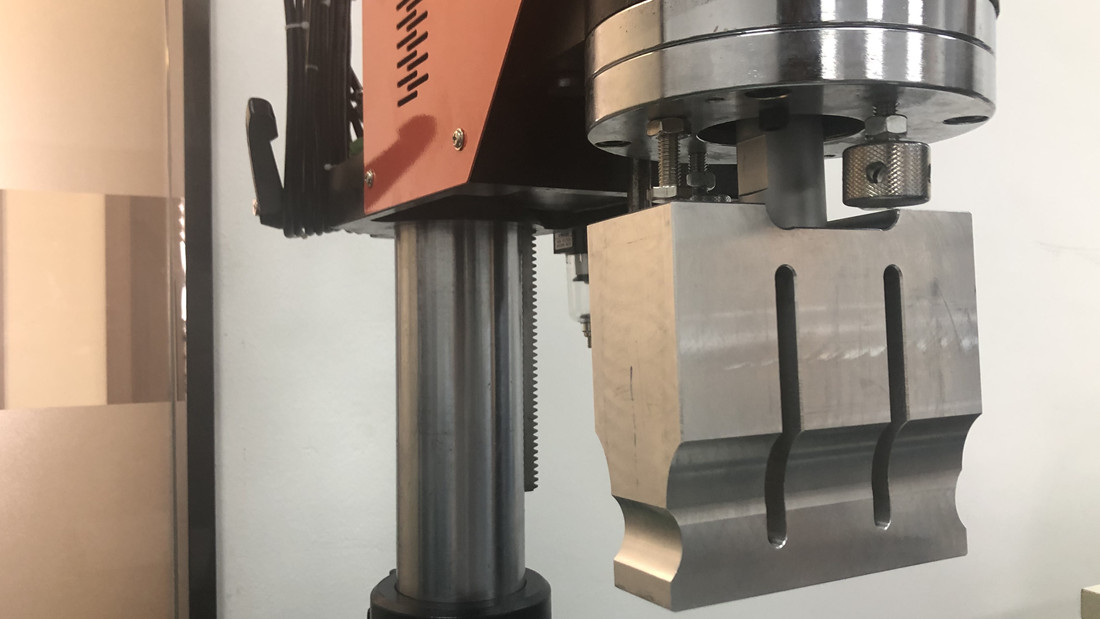

S20-WP2000 Ultrasonic Plastic Welder

Principle

The ultrasonic welding machine S20-WP2000 Series is suitable for welding operations of thermoplastic parts from medium to large size. This technique is fast, efficient, non-contaminating and requires no consumables. In addition to welding, ultrasonic processes can be used to insert, stake, stud weld, degate, and spot weld thermoplastics as well as seal, slit, and laminate thermoplastic films and fabrics. Ultrasonic components can be easily integrated into automated systems.

Cheersonic’s Ultrasonic Plastic Welder is available in multiple control modes: time, energy, peak power, collapse and absolute distance, and that can be directly mounted into electrical enclosures, and custom converters.

Features

• Can be housed in sound enclosures and is suitable for integration into special purpose machines

• High process reliability

• Repeatable welding force

• Simple tool change and quick setup

• Clean and free of debris

• Available in below frequencies: 15 kHz & 20kHz & 28kHz & 30 kHz &35 kHz & 40 kHz

• Easy to use and easy to use

Applications

The Ultrasonic Welding Machine S20-WP2000 is suit for the field of plastic and fabric, such as plastic toy, plastic jar, mask and so on.

With our full customization service for OEMs, we can respond to unique customer requirements, and build components, horns and blades to meet the specific needs of your system configuration and processing application.

| Name | S20-WP2000 Ultrasonic Plastic Welders |

| Power Rating: | 2000watts |

| Frequency | 20kHz |

| Dimensions: | 380x285x140mm |

| Voltage: | 110v,50/60Hz/220V |

| Generator: | Power cable |

| Converter: | Converter cable |

| Horn: | Wrench Set |