Project Description

Low-E Glass

Low Emissivity glass is also called low-e glass, low-e is short for Low Emissivity in English. Low-e glass that is using vacuum magnetron sputtering method on the glass surface plating contains a layer or two or even three layer of silver film system, to reduce the energy absorption or control the energy exchange between indoor and outdoor, safeguard vity comfort of life and work, and thus achieve the goal of environmental protection and energy saving.

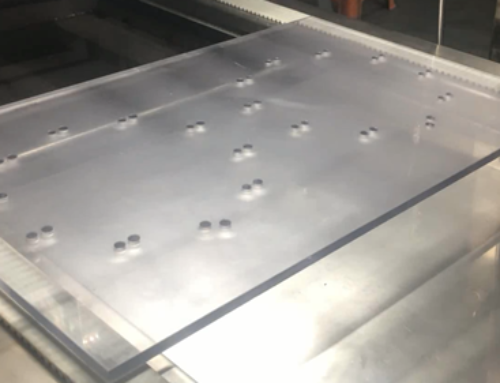

Low-E Glass Results

CHEERSONIC glass coating spray systems provide maximum efficiency and control of deposition parameters due to the soft nature of ultrasonic spray, and non-clogging atomization process. Unlike pressure nozzles, liquid is not forced through the nozzle orifice with pressure, but instead flows onto the nozzle’s atomizing surface where the spray is broken into droplets of almost identical size. Up to 80% reduction in spray material, as well as drastic reductions in maintenance, cleanup and exhaust requirements are reported with our ultrasonic spray systems.

The Effect of Ultrasonic Spraying Machine

CHEERSONIC developed ultrasonic atomization spraying equipment spraying fine particles having a 10 ~ 100μm, coating evenly dense coating, Low-E Glass guarantee of low emissivity. And because the ultrasonic atomization spraying equipment with high efficiency, low cost, quality and other characteristics, I believe ultrasonic atomization spraying equipment will be widely used in the Low-E Glass coating process in the near future.

Low-E Glass Coating Spraying Video

Standard Unit Spraying Solutions

Standard -Ultrasonic Nozzle

Standard -Ultrasonic Generators

Automatic-Production Spraying Solutions

Automatic–UAM3000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine