Project Description

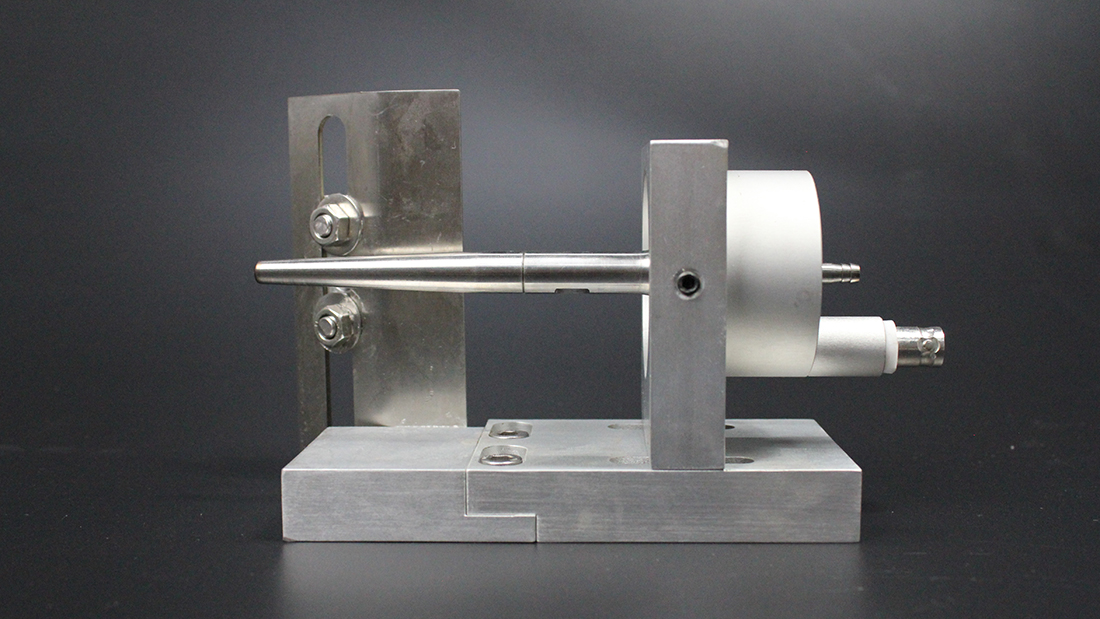

Inline Ultrasonic Spraying Machine

Product Description

Inline ultrasonic spray machine because of its characteristics are used in the manufacture and spraying of precision instruments. And the most common is involved in medical equipment surface coating, high-end electronic products, spraying. In the past inline ultrasonic spraying machine production technology for the well-known foreign companies have mastered the domestic in this area has been in a blank, leading to intervention in medical products demand depends on imports. CHEERSONIC ultrasonic liquid spray as the industry leader in not only the development of 120khz ultrasonic atomization spray equipment, more companies to provide ultrasonic spray coating line program to achieve automatic sterile, dust-free operation, precision instruments and equipment for the nationalization of manufacturing to provide more possibility.

Program Characteristics

In order to establish good relations of cooperation, CHEERSONIC provide free testing and trial services.

Free Testing

CHEERSONIC offers free testing to help customers understand the performance and compatibility of ultrasonic atomization spray products. The following steps, online message or telephone consultation, our sales engineers will be given within 24 hours of the corresponding preliminary advice, after consultation to determine the program submitted to the technical engineer review, for less than technical engineers and customers for further consultation and resolution, this The process will be carried out several times to achieve the optimal program, sample test, technical engineers will be based on the actual test results are given the final program.

Trial Service

If you want to test the effectiveness of ultrasonic atomization spray line equipment in your own business long-term operation, you can hire the existing standard equipment. If necessary, can be a message or telephone to my company, sales engineers will contact you within 24 hours of consultation with specific trial services.

Product Features

• Pipelining

• Customized solutions fit perfectly with your existing production lines

• Integrated operation, simple operation

• Sterile, dust-free operation

• Ultra-low flow, continuous or intermittent operation, to improve the spraying efficiency

• Gentle spray characteristics to replace conventional pressure spray

The use of ultrasonic spraying line program can achieve results

• 80% reduction in material consumption

• Reduce the waste of over-spraying and reduce the pollution caused by spraying

• Reduce scrap rates

• Almost no component wear

• Reduced maintenance and downtime

• Long-term spray results are consistent

• The coating is uniform and compact

• Achieve a sterile, dust-free environment

Main configuration

• Control system: self-developed 6-axis control system

• Can be set to automatic mode, jog debugging mode, with security system

• Mechanical drive: Servo motor

• Support: aluminum alloy, surface oxidation

• Surrounded with acrylic window

• Touch screen: 7-inch touch screen, friendly human-computer interaction interface

• Spray height can be set, programmable spraying process

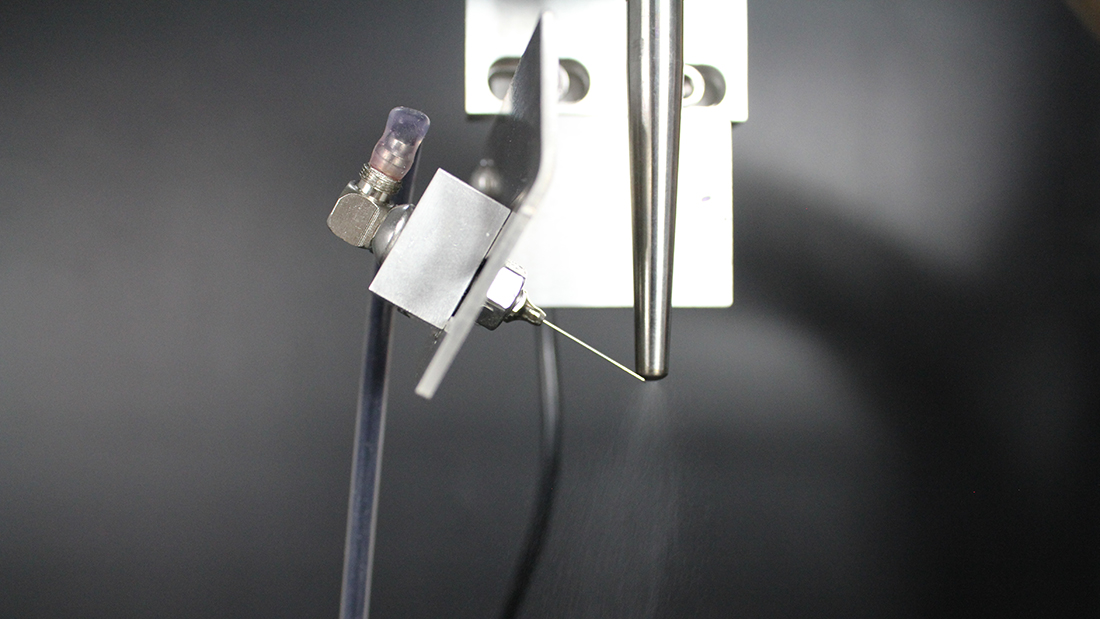

• Spray head: high-strength titanium alloy, can be configured with air flow guide, external guide spray system

Ultrasonic atomization spray technology is used almost any kind of substrate coating, to achieve a uniform micron thickness of the coating, and even nano-coating thickness. In addition, ultrasonic atomization spray technology is applied to:

• Medicine: stent spraying, catheter coating, balloon coating, blood sampling, medical gauze spraying

• Electronics: sensor coating, lens coating, touch screen spraying, digital product coating

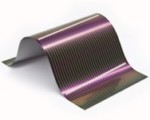

• Energy: solar thin film coating, solar photovoltaic panel spraying, polysilicon solar panel spraying

• Glass: Stained glass, anti-reflective glass, scratch-resistant glass, glass

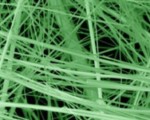

• Nanomaterials: graphene coating, nano-pigments, carbon nanotube / nanowire coatings, nano-coatings