Project Description

Ultrasonic Lace Stitching Machine

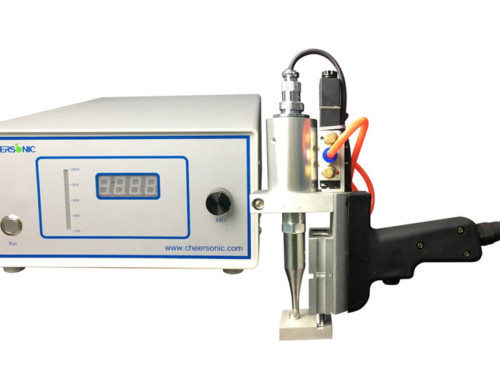

Ultrasonic Lace Stitching Machine – Ultrasonic Welding Services – Cheersonic

The high-frequency electric energy is converted into high-frequency vibration energy by the ultrasonic generator, and the ultrasonic energy is transmitted to the welding surface of the non-woven fabric by the welding head. The vibration energy instantly causes the molecules of the work to be rubbed and reaches the melting point of the plastic or non-woven fabric. Because non-woven fabrics dissipate heat relatively slowly, the solid materials of non-woven fabrics will melt quickly, and the joint strength is close to that of a whole piece of continuous material. As long as the joint surface of the product is designed to match, it can be completely sealed and welded. The use of ultrasonic welding eliminates the need for needles and threads, saves the trouble of frequent needle changes, does not have the broken joints of traditional stitching, and can also neatly cut and seal non-woven textiles. Different flower wheels, molds and cutters can be designed according to product needs to achieve excellent hemming, welding, fusion cutting, embossing, crimping, sewing, and cutting effects.

Ultrasonic non-woven fabric pressing machine:

Ultrasonic lace machine is the use of ultrasonic technology, machine design sewing machine structure, ultrasonic drives the flower wheel, spot welding head, trim welding head and other processing devices. Ultrasonic has a good welding effect on plastics, and non-woven fabrics are made of polypropylene (PP material) pellets, so ultrasonics are very good for processing non-woven fabrics, such as chemical fiber, polyester, polypropylene, nylon, spandex, acrylic, etc. textile.

Ultrasonic sewing machine applicable products: clothing lace, car covers, hand straps, shopping bags, masks, surgical gowns, lampshades, filters, disposable products, protective clothing, etc., multi-purpose non-woven products, medical industry, daily necessities industry, packaging Industry, automobile industry, decoration industry, toy industry.