Project Description

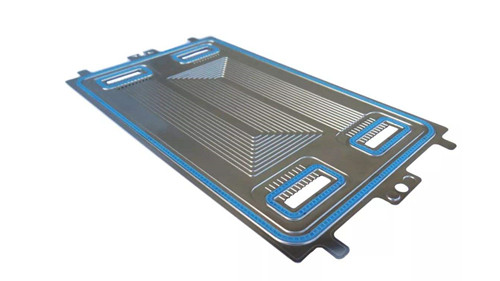

Metal Bipolar Plate Material And Coating

Metal bipolar plate material

Metals and alloys have good mechanical properties and electrical conductivity, and are cheap; passivation films are easily formed on the metal surface in the service environment. Although these passivation films slow down the corrosion rate, the conductivity of these passivation films is low, which leads to The output power and service life of the fuel cell are reduced. The conductivity and corrosion resistance of metal materials under service conditions are contradictory. How to solve this contradiction and achieve a reasonable match between the conductivity and corrosion resistance of materials is a major bottleneck in the improvement of metal bipolar plate technology. At present, the most effective way to solve the problem of conductivity and corrosion resistance is to modify the metal surface. The coated metal bipolar plate can improve the corrosion resistance of the bipolar plate while ensuring good conductivity, ensuring the entire The service life of the system is increased. However, the performance of the modified surface coatings of different metal materials is different. Therefore, choosing the right substrate and coating materials is the key to the wide application of metal bipolar plates.

Metal bipolar plate base material

The base materials of metal bipolar plates mainly include stainless steel, aluminum, and titanium alloys. Such materials have high strength, good toughness, and good electrical conductivity and processing properties. For example, the conductivity of the metal bipolar plate can reach 10 to 100 times that of graphite, and due to its excellent mechanical properties, the thickness of the metal bipolar plate can be less than 1 mm, which can greatly reduce the volume of the battery pack. However, metal materials are prone to corrosion in the battery environment (pH=2~3, T=80°C), resulting in a decrease in battery performance. Studies have found that the dissolved metal ions will diffuse into the battery membrane, causing the conductivity of the battery membrane to decrease. Some scholars believe that the corrosion resistance of stainless steel bipolar plates is not only related to Cr, but also affected by the alloying element Mo. And pointed out that the battery performance is mainly related to the composition of stainless steel, and the contact resistance is related to the content of Cr and Ni.

Studies have shown that Cr in stainless steel can improve corrosion resistance, but the Cr2O3 oxide layer formed on the surface will produce large interface resistance. Scientists have studied bipolar plates with various alloys such as stainless steel, titanium, aluminum, and nickel. The results show that an oxide layer with extremely high resistivity is formed on the surface of the alloy, and the contact resistance increases with the thickness of the oxide layer, causing the battery The output power has dropped significantly. Comparing the interface resistance of different alloys, it is found that under the pressure of 2.2MPa, the interface resistance of different alloys is 321 stainless steel>304 stainless steel>347 stainless steel>316 stainless steel>pure Ti>310 stainless steel>904 stainless steel>Inonel800 high temperature alloy>Inonel601 high temperature alloy The order decreases and is consistent with the decreasing order of the oxide layer thickness. In addition, the surface of a series of stainless steel base materials was measured, and it was found that Mn element helps to form a passivation film with higher conductivity, and the presence of nickel in the outer area of the passivation film will form nickel oxide with oxygen. The combination of compound and chromium/iron oxide will improve the conductivity of the passivation film. In fact, a large amount of experimental data shows that ordinary stainless steel is not suitable for bipolar plate material, which is caused by high contact resistance caused by non-conductive oxide. Compared with stainless steel, nickel-based corrosion-resistant alloys (superalloys) exhibit excellent corrosion resistance in the battery environment, and the contact resistance of superalloys is lower than that of graphite. Studies have shown that the contact resistance of pure titanium bipolar plates in water vapor is equivalent to that of graphite bipolar plates, which is slightly higher than graphite in hot water, but the potential of pure titanium will decrease significantly during long-term battery operation, which leads to Battery performance deteriorates. On the basis of the pure titanium matrix exhibiting good corrosion resistance, further adding elements such as Nb and Ta can improve the conductivity of the TiO2 passivation film on the surface of the titanium alloy.

In summary, the metal bipolar plate has good strength and can basically meet the mechanical performance requirements of the bipolar plate. However, the metal bipolar plate has poor corrosion resistance in the proton exchange membrane fuel cell environment, and the dissolved metal ions can poison the proton exchange membrane, resulting in a decrease in battery performance. The corrosion resistance of the metal bipolar plate can be improved by adding some alloying elements to the metal material. The reason is that these alloying elements will form oxides in the service environment. These oxides act as isolation and passivation on the metal surface and reduce the material. The corrosion rate. However, the low conductivity of these oxides reduces the output power and service life of the fuel cell. The material composition is different, the thickness of the oxide film formed on the surface is also different, and the order of increasing the thickness of the oxide film is basically the same as the order of increasing the contact resistance. It can be seen that while the metal bipolar plate improves corrosion resistance, its conductivity decreases, and the increase in corrosion resistance is inversely proportional to the decrease in conductivity. Although the addition of alloying elements to the metal can improve the conductivity of the passivation film, it cannot meet the performance requirements of the bipolar plate. Therefore, metal materials cannot be used directly as bipolar plates.

Metal bipolar plate coating material

In view of the contradiction between the conductivity and corrosion resistance of metal materials, the current solution is mainly to modify the surface of the metal bipolar plate, and the most researched is the metal surface coating. Since the mechanical and physical and chemical properties of the coating material and the metal and alloy substrate are different, it is necessary to select a coating material with good matching and bonding with the substrate to avoid electrochemical corrosion in the battery environment. Here, the coating materials are classified and introduced according to the stainless steel matrix and the lightweight metal and alloy matrix.

(1) Stainless steel bipolar plate coating

Stainless steel has excellent electrical conductivity/thermal properties, corrosion resistance and mechanical properties, and is the first choice for bipolar plate materials. However, this kind of material has poor corrosion resistance in the battery environment, and the conductivity of the passivation film formed on the surface is low. When the contact resistance increases by 25mΩ·cm2, the battery power will lose 2% to 5%. How to select the appropriate coating or adopt the appropriate surface treatment method to improve the corrosion resistance and chemical stability of the stainless steel bipolar plate while reducing the contact resistance has become the key technology of research and development. Stainless steel coating materials mainly include graphite, conductive polymers, metal nitrides, metal carbides, and precious metals.

Currently commonly used stainless steel materials mainly include SS304, SS316 and SS446 alloys. The corrosion current density of the uncoated SS304 stainless steel base material in the battery environment is 2.6μA/cm2, and the contact resistance is 140mΩ·cm2; when the NbC layer is coated on the SS304 base material, the corrosion current density and contact resistance can be reduced respectively To 0.051~0.058μA/cm2 and 8.47mΩ·cm2

Compared with SS304 stainless steel substrate, the contact resistance of SS316 stainless steel is slightly lower (123mΩ·cm2), but the corrosion current density is higher (5.7μA/cm2), and coating on the surface can greatly improve its corrosion resistance and electrical conductivity. For example: the surface is plated with NbC, the corrosion current density is 0.051~0.058μA/cm2, the contact resistance is 8.47mΩ·cm2; the surface is plated with CrN+Cr2N, the corrosion current density can be reduced to 0.136μA/cm2, the contact resistance can be reduced to 7.0mΩ ·Cm2, these coatings combined with the substrate show good corrosion resistance and resistivity. Different from the above coating materials, by doping Cr in the C film, the coating material formed on the SS316 stainless steel substrate shows very excellent corrosion resistance and electrical conductivity (after the surface is coated with a carbon layer containing Cr , Its corrosion current density is 0.00316~0.316μA/cm2, and the contact resistance is 2.8mΩ·cm2), which can fully meet the performance indicators of the bipolar plate. The coating formed by mixing other alloy elements in the C film can be used as one of the spare materials for the stainless steel bipolar plate. In addition, the coating materials with better performance include Ti-(Ti,Cr)N-CrN, Zr-C/aC (unshaped carbon), Cr-NC, Cr-C, etc. These coatings also have good Both corrosion resistance and electrical conductivity can be used as alternate coating materials for SS316 stainless steel bipolar plates. However, TaNx (corrosion current density is 1~10μA/cm2, contact resistance is 42~82mΩ·cm2) [37], PbO2 (corrosion current density is 1.37~5.34μA/cm2) [40] and CrN (contact resistance is 23mΩ ·Cm2) and other coating materials that do not meet the performance requirements of the bipolar plate, which may be due to the poor bonding between the coating material and the substrate, which causes the corrosion current density and contact resistance to increase.

Coating on SS304 stainless steel and SS316 stainless steel significantly improves the performance of stainless steel. Many stainless steel materials after coating can reach the performance indicators of bipolar plates. However, the corrosion current density and contact resistance exhibited by the coating of the same material combined with stainless steel of different materials are different. For example, if TiN is plated on SS304 stainless steel and SS316 stainless steel at the same time, the corrosion resistance current density and contact resistance of SS304 stainless steel are 0.0145μA/cm2, 30mΩ·cm2, and the corrosion resistance current density and contact resistance of SS316 stainless steel are 1.0~2.5, respectively. μA/cm2 and 10mΩ·cm2. It is found by comparison that the contact resistance of coated SS316 stainless steel is lower than that of coated SS304 stainless steel, but the corrosion current density is higher than that of SS304 stainless steel. This shows that the bonding force and compatibility between the same coating and different alloy substrates are different. A similar situation is the plating of CrN on SS304 stainless steel and SS316 stainless steel (corrosion current density after plating CrN on SS304 stainless steel is 0.00029μA/cm2, contact resistance is 19mΩ·cm2, corrosion after plating CrN on SS316 stainless steel The current density is 0.1~0.3μA/cm2, and the contact resistance is 23mΩ·cm2). Therefore, when plating a coating on a metal substrate, not only the performance of the coating material, but also the matching and bonding between the coating material and the substrate must be considered.

Compared with SS304 and SS316 stainless steel, the corrosion current density (10~15μA/cm2) and contact resistance (190mΩ·cm2) of SS446 stainless steel are relatively high, and the price is more expensive. Therefore, in recent years, research on this type of bipolar plate material less. In terms of reducing corrosion current density and conductivity, a better method is surface nitriding. Through surface modification treatment, the corrosion current density of SS446 stainless steel can be reduced to 0.1~1.0μA/cm2, and the contact resistance can be reduced to 6.0mΩ·cm2 . The surface nitriding treatment significantly improves the corrosion resistance and conductivity of SS446 stainless steel, and it can also become one of the alternative materials for bipolar plates.

(2) Light metal bipolar plate coating

As light metals, titanium and titanium alloys, aluminum and aluminum alloys have the characteristics of high specific strength, good thermal and electrical conductivity, and easy processing. They are good materials for making bipolar plates. They have an advantage in improving the specific power of battery packs, and are especially suitable Bipolar plates for special purpose proton exchange membrane fuel cells. Here, we mainly introduce aluminum alloy base and coating materials and titanium alloy base and coating materials.

① Aluminum alloy substrate and coating

Compared with stainless steel, the advantages of Al alloy are low density (65% lighter than stainless steel), low resistivity (1/5 of stainless steel), high thermal conductivity (8 times of stainless steel), and easy processing. The corrosion resistance in the environment is poor and cannot meet the performance requirements of the bipolar plate. Therefore, the Al alloy must be surface treated to be used on the bipolar plate.

For example, for AA5083 alloy, the corrosion current density and contact resistance before coating are 390μA/cm2 and 34mΩ·cm2 respectively. After a layer of CrN is coated on the surface, the corrosion current can be reduced to 57.42~79.12μA/cm2, the contact resistance It can be reduced to 6.0mΩ·cm2; AA5052 alloy, the corrosion current density and contact resistance before coating are 268.8μA/cm2, 61.58mΩ·cm2, and a layer of C, C-TiN or C-CrN is coated on the surface The post-corrosion current densities were 4.6μA/cm2, 0.4μA/cm2 and 0.5μA/cm2, respectively, and the contact resistances were 6.39mΩ·cm2, 4.08~6.39mΩ·cm2 and 4.08mΩ·cm2. It can be seen that the Al alloy surface coating has improved its corrosivity and conductivity to a large extent, which significantly increases the service life of Al alloy in the battery environment. In addition to the above coating materials, the coating materials with good performance include graphene oxide (the current density of the coated AA1060 metal is less than 1.0μA/cm2, and the contact resistance is less than 5.0mΩ·cm2), Ni-Mo- P (the current density of the coated AA5052 metal is 0~4.78μA/cm2, and the contact resistance is 0.023mΩ·cm2), Au/Ni-P (the corrosion current density of the coated AA5052 metal is 0~3.46 μA/cm2, the contact resistance is 4.0mΩ·cm2), C-CrN (the current density of the coated AA5052 metal is 0.84~1.55μA/cm2, and the contact resistance is 4.08mΩ·cm2).

Compared with this, the Al alloy coating with poor performance mainly includes TiN (the current density of the coated AA5052 metal is 34.4μA/cm2, and the contact resistance is 20.8mΩ·cm2), CrN (the coated AA5052 The current density of the metal is 36.8μA/cm2, Ni-Co-P (the current density of the coated AA1050 metal is 662.3μA/cm2), etc. Although the coated Al alloy has greatly increased the double The corrosion resistance and electrical conductivity of the plate material still cannot reach the performance indicators of the bipolar plate.

The same kind of coating is plated on different substrates, there will be obvious differences in corrosion resistance and conductivity. For example, the Ni-Co-P coating is plated on the surface of pure Al, AA1050 alloy, AA6061 alloy, AA3004 alloy, and the corrosion current densities are 4.0μA/cm2, 1.96μA/cm2, 32.03μA/cm2 and 11.94μA/cm2, the contact resistance is 142.35mΩ·cm2, 27.05mΩ·cm2, 77.75mΩ·cm2 and 209.25mΩ·cm2. Therefore, the coating material must have good bonding and matching with the substrate in order to show good comprehensive performance and meet the service conditions of the bipolar plate. The performance of the coated Al alloy material in the simulated battery environment at different temperatures is quite different. For example, after plating a layer of Ni-Co-P on the surface of pure aluminum and placing it in a simulated battery environment at 25°C and 70°C, the corrosion current densities are 4.0μA/cm2, 565.4μA/cm2; After AA1050 is coated with a layer of Ni-Co-P and placed in a battery environment at 25°C, its corrosion current density is 1.96μA/cm2, and placed in a battery environment at 70°C, its corrosion current density is 662.3μA/ cm2.

②Titanium alloy substrate and coating

Titanium alloy materials have the advantages of low density, high specific strength, corrosion resistance, and easy processing. However, passive films will also form on the surface of titanium alloys under high temperature or acidic conditions, resulting in increased contact resistance between the membrane electrode diffusion layer and the bipolar plate. Large, reduce the output power of the fuel cell. Since a passive film with low conductivity is easily formed on the surface of titanium alloy, titanium alloy cannot be directly used as a bipolar plate. Similar to stainless steel and aluminum alloys, titanium alloys can be coated on the surface to improve their corrosion resistance and electrical conductivity to meet the performance requirements of bipolar plates. As shown in Table 4, the corrosion current density of uncoated Ti-6Al-4V in the simulated battery environment is 5.48~7.46μA/cm2, and the contact resistance is 87mΩ·cm2. By coating a layer of ZrC or ZrCN on the surface The corrosion current density is 0.39μA/cm2 and 0.336~15.7μA/cm2, respectively, and the contact resistance is reduced to 9.6mΩ·cm2 and 11.2~11.71mΩ·cm2 respectively; the corrosion current density and contact resistance of pure Ti in a simulated battery environment They are 0.042μA/cm2 and 37mΩ·cm2, and the corrosion current density and contact resistance after TiN plating on the surface are 0.0086μA/cm2 and 2.4mΩ·cm2, respectively. It can be seen that the coated Ti alloy can basically meet the performance requirements. Compared with the above-mentioned coating materials, Zr plating on the surface of Ti-6Al-4V exhibits lower contact resistance (40mΩ·cm2), which cannot meet the performance requirements of bipolar plates.

In summary, the performance of different metal materials in the battery environment is different, and how to choose a suitable bipolar plate substrate is also the key to the wide application of fuel cells. The corrosion current density of stainless steel and titanium alloy in the simulated battery environment is close, but the contact resistance is obviously different. The order from large to small is SS304, SS316, Ti-6Al-4V, and pure Ti. Compared with stainless steel, titanium alloy has a similar corrosion current density and has a lower contact resistance. Therefore, in terms of comprehensive corrosion resistance and conductivity, titanium alloy is more suitable as a base material for bipolar plates than stainless steel. Compared with stainless steel and titanium alloy, aluminum alloy has good electrical conductivity in simulated battery environment (SS304>SS316>Ti-6Al-4V>AA5052>pure Ti>AA5083), but the corrosion current density is too large (AA5083>AA5052> Ti-6Al-4V>SS316>SS304>pure Ti), which may be caused by the inconsistency of the oxide film formed on the aluminum alloy surface.

Therefore, in terms of overall performance, stainless steel and Ti alloys are more suitable as base materials for bipolar plates than Al alloys. The passivation film formed on the metal surface reduces the corrosion rate of the material, but increases the contact resistance. By coating the metal surface, the corrosion resistance and electrical conductivity of the metal material surface can be improved. After plating CrN on the surface of different metal base materials, the current density and corrosion resistance of the bipolar plate materials have been significantly improved. After coating, the corrosion current density of different alloy materials in the simulated battery environment is AA5083, SS316, SS304, and the order of contact resistance is SS304, SS316, AA5083.

In general, CrN plating on stainless steel has achieved excellent performance and can meet the performance requirements of bipolar plates. However, compared with stainless steel, CrN plating on aluminum alloy exhibits a larger corrosion current density, which may be caused by defects in the contact between the CrN coating and the Al alloy surface. The order of corrosion current density after TiN plating on the surface of different metal materials is AA5052, SS316, SS304, Ti, and the order of contact resistance is SS304, AA5052, SS316, pure Ti. It can be seen that pure Ti and TiN coated on the surface of SS316 stainless steel show excellent corrosion resistance and conductivity in the simulated battery environment. However, the coated SS304 stainless steel exhibits poor electrical conductivity, which may be caused by the poor bonding between the coating and the substrate. The contact resistance and corrosion current density of the coated AA5052 are both high. The cause of this situation may be the existence of defects in the interface contact, which leads to electrochemical corrosion, which increases the corrosion current density and contact resistance. In summary, titanium alloys and stainless steels are more suitable as bipolar plate base materials than Al alloys.

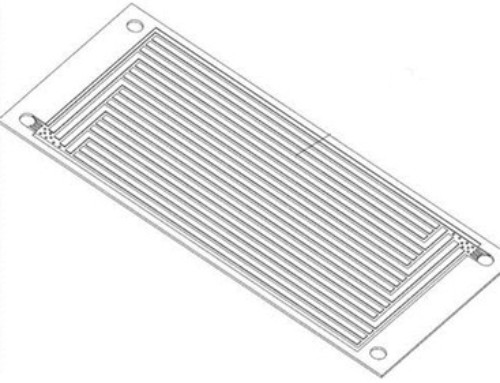

How to prepare excellent metal bipolar plate coating

Ultrasonic spraying technology can prepare fuel cell coatings with high uniformity and high density, such as depositing platinum carbon, palladium carbon, ruthenium carbon and other catalyst coatings on Nafion proton exchange membranes, and metal bipolar plate coatings, which are dense, uniform and No swelling phenomenon. Therefore, the ultrasonic spraying technology has been widely regarded by the industry as the key preparation technology of the membrane electrode of the proton exchange membrane fuel cell. Ultrasonic spraying equipment can spray a variety of different metal alloys, including the preparation of platinum, nickel, iridium and ruthenium-based fuel cell catalyst coatings, as well as PEMs, GDLs, DMFCs (direct methanol fuel cells) and SOFCs (solid oxide fuels) Battery). The battery manufactured by this technology has the characteristics of high battery load and high battery efficiency.