Manual Ultrasonic Cutting for Caramels

Manual Ultrasonic Cutting for Caramels is not only beautiful but also practical. Let’s take a look at this magical technology together!

Ultrasonic cutting technology is a very advanced cutting technique that minimizes the friction between the cutting blade and the material through high-frequency vibration, thereby achieving efficient and accurate cutting. In caramel production, ultrasonic cutting technology can also exert its powerful advantages. Compared to traditional cutting methods, ultrasonic cutting not only has a faster speed, but also a smoother cutting surface, without problems such as uneven cutting and breakage.

About Cheersonic

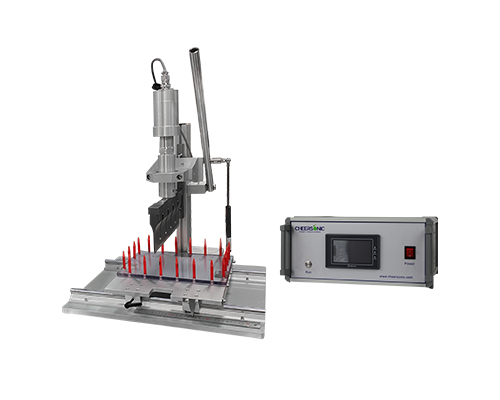

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions