Project Description

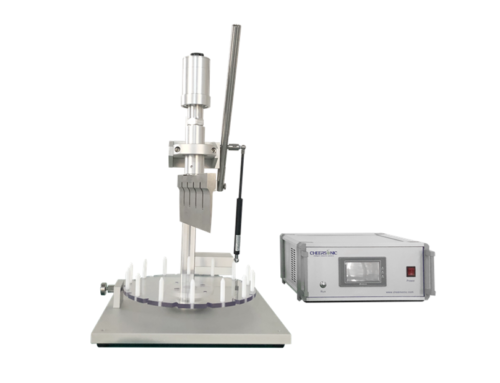

UFM3500S Sandwiches Ultrasonic Cutting Machine

Product Description

Sandwich Ultrasonic Cutting Machine for continuous cutting of sandwiches, bread and so on. Advanced ultrasonic cutting system for precision and product sensitive cutting, cutting without waste generated. The machine uses titanium alloy blade, vibration 20,000 times per second, to achieve perfect cutting. The blade can immediately get high-power cutting energy, so that the machine can easily cut the most difficult products, will not twist or tear. Through the conveyor belt transport, the machine runs 60 sandwiches per minute, through the integrated touch screen to adjust, sandwich height of up to 100mm.

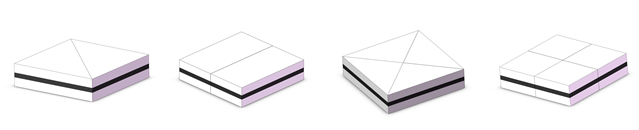

Cutting Mode Schematic

Actual Cutting Effect Image

Key Features

• Cut 60 sandwiches per minute

• Cut up to 100 mm

• The cut product is not deformed

• Can be used as a standalone machine or as an embedded solution

• Advanced product feeding device

• Design of sanitary and safety doors

Applications

This ultrasonic cutting equipment production line is designed for industrial production of sandwiches in large quantities, in addition to cutting chicken rolls, square cake diagonal cut and so on.

| UFM3500S Sandwiches Ultrasonic Cutting Machine | |

| Dimensions (length) x (width) x (high) | 2100*650*1800 |

| Weight | 350Kg |

| Rated power | 3.5kw |

| Cutting speed | 60 knives / min |

| Maximum cutting size | The maximum width of the product is 300mm |

| Maximum effective cutting height | 65 mm |

| Number of cutting knives | 1 |

| Cutting knife size | 200mm (Other optional) |

| Whether it can be rotated | Can not |

| Cut type | sandwich and wrap (rolls) |

| Conveyor belt (several) | Yes (One belt) |

| Rack structure | Stainless steel |

| Safety protection system | Safety protection door |

| Screen | 7 inch touch screen |

| Control cabinet | Built-in |

| Control System | Multi-axis Control System |

| Cutting knife control system | Servo motor |

| Electric supply | Single phase, 220v, 50-60Hz |

| Compressed air connection | Max. 0.4Mpa For fixture only |

| Product into and out of material | Automatically or manually |

| Machine mobility | Pully |