Project Description

Optical Lens Coating Ultrasonic Spray

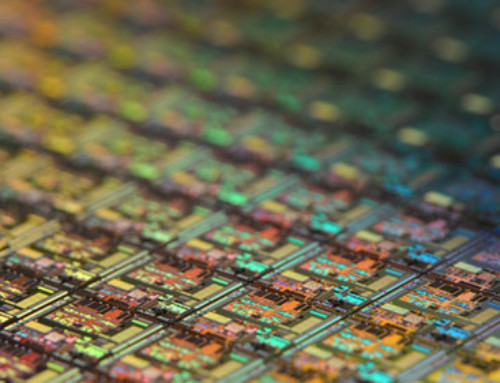

Both inorganic material and organic material made of glass lens, in the course of everyday use, with dirt or gravel friction can cause the lens wear, the lens surface scratches. Compared with glass, hard degree of organic materials is lower, are more likely to produce scratches. Through a microscope, we can observe scratches on the surface of the lens is mainly divided into two kinds, one is scratches caused by gravel, shallow and small, Dai Jingzhe is not easy to detect; Another is produced by larger gravel scratches, deep and surrounding rough, in the central area will affect vision.

As the glasses demand increases, the preparation of the coating technology is becoming more and more diversified. In many methods, ultrasonic spraying technology as an emerging technology plays a more and more important role on the system research is helpful to guide the development of optical lens coating preparation process, increase the technological reliability, optimizing the coating quality and reduce development costs.

For ultrasonic spraying system by detecting experiment results show that the power and flow rate and gas pressure affect the ultrasonic atomization model, when the power is reduced, when flow rate increases, the spray particle size increase, And when the gas phase pressure and spray section changes, spray particle size change small, means that the gas phase under the action of ultrasonic spray more stable; In terms of particle size distribution, when flow rate increases, the spray narrow particle size distribution; In addition, ultrasonic spray particles in the gas phase under the action of no secondary crushing, near the nozzle position, between particles merger occurs easily, but the total ratio is small. Finally, using the analysis of ultrasonic spray particle size evenness index between 7.11 ~ 11.48, is superior to the conventional spraying technology for spray quality, and spray control, operating flexibility, energy-saving sex is greatly increased.

Ultrasonic Atomizer Spraying Video

Standard Unit Spraying Solutions

Standard – Ultrasonic Nozzle

Standard – Ultrasonic Generators

Automatic-Production Spraying Solutions

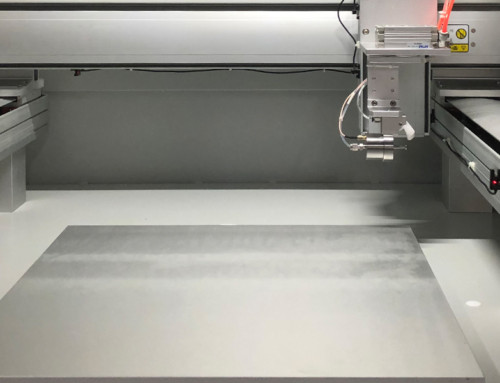

Flat Type Ultrasonic Spraying Machine

Automatic – UAM3000 Ultrasonic Spraying Machine

Automatic – UAM4000 Ultrasonic Spraying Machine

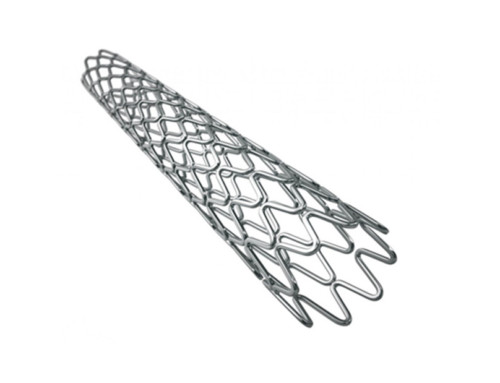

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine