Project Description

Nano SiOx Modified Ultrasonic Spray

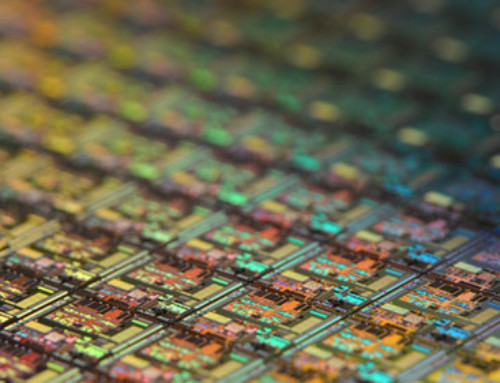

At present our country to adopt the post-processing accounts for only 30% of the total output, fruit storage of fruit is less than 20% of total output, coating preservation technique because of its simple use, convenient, the advantages of low cost, good effect, is widely used at home and abroad. Abroad, researchers mainly use of electronic microscope and diffraction instrument and other advanced equipment, the structure and performance of the membrane to do quantitative analysis, such as choosing best conditions and formula of film, it was found that nanoparticles SiOx small particle size, surface activity, be easy to enhance coating adhesion, form both can inhibit breathing, can also be anti-oxidation, sterilization, absorb the modified membranes with multi-functional properties such as ethylene or blend membrane. Now how to make uniform nano SiOx to nanoscale effectively dispersed coating on the plastic film is the key to this study.

CHEERSONIC using self-developed ultrasonic sprayer directly to the nanometer SiOx dispersion coating on the plastic film, the study of the preparation of nanometer SiOx thin film ultrasonic sprayer influence factors, and get the nano SiOx composite was made by the optimum process conditions of fresh-keeping film. The influence of three factors, respectively, of nanoparticle SiOx accounted, ultrasonic frequency of spraying machine, ultrasonic spraying time. CHEERSONIC using orthogonal experiment and single-factor experiment found that for the larger proportion of SiOx particles, is difficult to completely dispersed in the ultrasonic spray, and when the mass fraction of SiOx nanoparticles is small, easy to be fully dispersed evenly spray; When other conditions are consistent, ultrasonic atomizing spray droplets is smaller, the greater the sprayer frequency current CHEERSONIC has developed 120 KHZ ultrasonic sprayer atomized spray droplets of nano and micro level, the atomized spray droplets as easy to uniform coating; Ultrasonic atomization spraying time for larger impact factor. Some ultrasonic frequency, with the increase of spraying time, the film coating evenly to increase gradually, but the time is too long can lead to coating too thick.

Ultrasonic Atomizer Spraying Video

Standard Unit Spraying Solutions

Standard – Ultrasonic Nozzle

Standard – Ultrasonic Generators

Automatic-Production Spraying Solutions

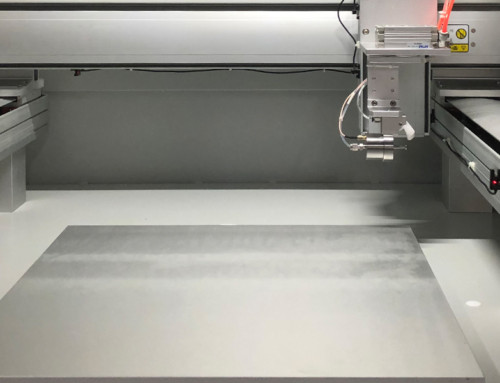

Flat Type Ultrasonic Spraying Machine

Automatic – UAM3000 Ultrasonic Spraying Machine

Automatic – UAM4000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine