Project Description

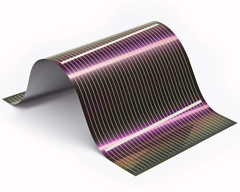

Thin Film Solar

A thin-film solar cell is a second generation solar cell that is made by depositing one or more thin layers, or thin film (TF) of photovoltaic material on a substrate, such as glass, plastic or metal. Thin-film solar cells are commercially used in several technologies, including cadmium telluride (CdTe), copper indium gallium diselenide (CIGS), and amorphous thin-film silicon (a-Si, TF-Si).

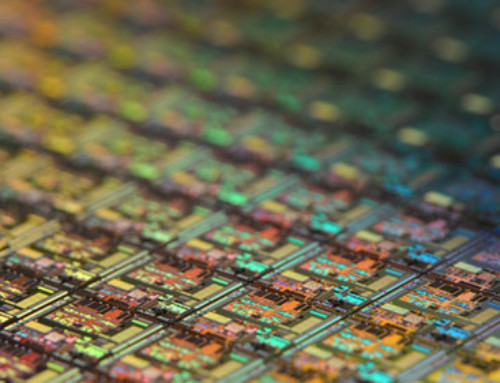

Thin Film Solar Coating Results

Ultrasonic spray nozzle technology has been used to create thin film solar of indium tin oxide (ITO) in the formation of transparent conductive films (TCF). ITO has excellent transparency and low sheet resistance, however it is a scarce material and prone to cracking, which does not make it a good candidate for the new flexible TCFs. Graphene on the other hand can be made into a flexible film, extremely conductive and has high transparency. Ag nanowires (AgNWs) when combined with Graphene has been reported to be a promising superior TCF alternative to ITO. Prior studies focus on spin and bar coating methods which are not suitable for large area TCFs. A multi-step process utilizing ultrasonic spray of graphene oxide and conventional spray of AgNWs followed by a hydrazine vapor reduction, followed by the application of polymethylmethacrylate (PMMA) topcoat resulted in a peelable TCF that can be scaled to a large size.

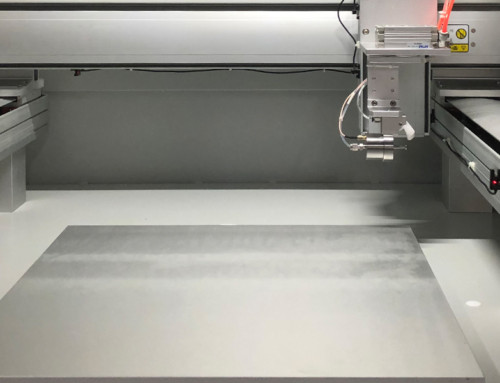

The Effect of Ultrasonic Spraying Machine

CHEERSONIC developed ultrasonic spray device can be used not only to the medical device surface coating, the preparation of other electronic materials can also be used for the PV. For the preparation of thin-film photovoltaic Its principle is to use ultrasonic atomization spraying device spraying liquid is atomized into ultra-fine droplets, with additional auxiliary air stream which is more uniformly attached to the surface of the substrate to form a uniform thickness controllability, high quality appearance coating the surface of the coating so as to solve poor uniformity, poor coating, spray coating, and productivity is low amount of uncontrollable problems existing in the prior art spraying, to achieve accurate spraying purposes. Compared with the prior preparation of traditional thin-film photovoltaic technology, CHEERSONIC research and development of ultrasonic spray equipment, with the preparation of photovoltaic thin film uniform and its thickness is thin, and similar thin-film photovoltaic every preparation quality.

Thin Film Solar Coating Spraying Video

Standard Unit Spraying Solutions

Standard – Ultrasonic Nozzle

Standard – Ultrasonic Generators

Automatic-Production Spraying Solutions

Flat Type Ultrasonic Spraying Machine

Automatic – UAM3000 Ultrasonic Spraying Machine

Automatic – UAM4000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine