Project Description

Silicon Solar Cells

Amorphous silicon (a-Si) is a popular solar cell material owing to its low cost and ease of production. Owing to disordered structure (Urbach tail), its absorption extends to the energies below the band gap resulting in a wide-range spectral response; however, it has a relatively low solar cell efficiency. The efficiency is higher in protocrystalline silicon and it has also been shown to improve stability, but not eliminate it. Protocrystalline Si also has a relatively low absorption near the band gap owing to its more ordered crystalline structure. Thus, protocrystalline and amorphous silicon can be combined in a tandem solar cell where the top layer of thin protocrystalline silicon absorbs short-wavelength light whereas the longer wavelengths are absorbed by the underlying a-Si substrate. Such two-layer cells can be produced at a relatively low temperature of 75 °C and have an efficiency of about 5%, and a four-layer cells yield an open circuit voltage above 3.1 V.

Silicon Solar Cells Coating Results

Ultrasonic Spray pyrolysis is a Chemical vapor deposition (CVD) method utilized in the formation of a variety of materials in thin film or nanoparticle form. Precursor materials are often fabricated through sol-gel methods and examples include the formation of aqueous silver nitrate, synthesis of zirconia particles, and fabrication of solid oxide fuel cell SOFC cathodes.

The Effect of Ultrasonic Spraying Machine

CHEERSONIC independently developed ultrasonic spray device, can achieve directional spraying solar energy, saving materials can save 90% of the raw material, thus avoiding the environmental pollution and the subsequent steps of the process. Currently, solar cells are the most advanced spraying technology. Currently CHEERSONIC developed ultrasonic spraying equipment has been developed on the basis of stand-alone operation of the pipeline system, streamline batch applications, greatly improving the rate of preparation, provide strong technical support for the realization of industrial production experiments. We can test for free, and give a lot of the best solution, including the production, secondary production, assembly line, and the optimized revamping existing production lines.

Silicon Solar Cells Coating Spraying Video

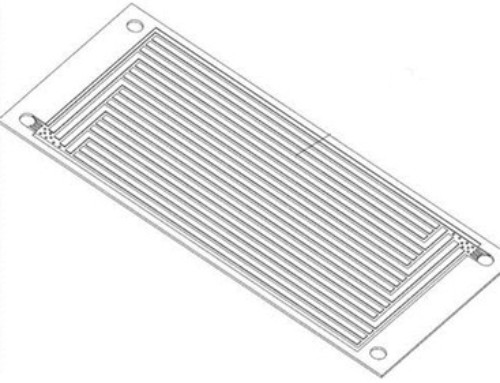

Standard Unit Spraying Solutions

Standard -Ultrasonic Nozzle

Standard -Ultrasonic Generators

Automatic-Production Spraying Solutions

Automatic–UAM3000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine