Project Description

Anti-static Liquid

Anti-static liquid anti-static durability is valid for several months or more, to reduce the plastic, glass, stainless steel and other products, surface resistance. Anti-static liquid main purposes: plastic products on the surface and packaging products to eliminate static electricity, sterilization; electronic components, electronic components storage box, IC tray, pipe and other surface anti-static; to prevent the production process, transportation, Discharge causes damage to the electronics.

The Common Use of Anti-static Liquid

The common use of anti-static liquid can be sprayed, rubbed, dip, painted in these four processes, rubbing and coating these two methods generally require manpower to operate the implementation, so there will always be rubbing, uneven coating, or Other causes of human error. And soaked in this way only the treated object directly in the anti-static liquid liquid, and then removed from the liquid can be dry, this approach is low cost, simple operation, suitable for processing less demanding products but the processing of electronic components Can take this way.

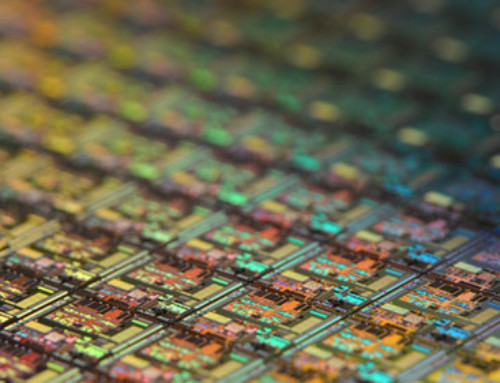

Anti-static Liquid Ultrasonic Spray

With the development of spraying technology in recent years, the new spray coating technology is very popular, ultrasonic spray power consumption is low, the average droplet produced by small particles, uniformity, droplets directly sprayed on the surface of the treated material , Anti-static liquid utilization rate is high, so it is considered a green anti-static liquid spraying process. However, the atomization droplets of the atomized surface of the ultrasonic nozzle are small in initial velocity and are susceptible to disturbing the surrounding air. If there is no auxiliary air flow, it is difficult to form a fixed spray pattern, and the number of droplets after atomization is large Movement process, will re-cohesion, the formation of large droplets, is not conducive to access to high-quality anti-static liquid spray products such as electronic components, it is difficult to achieve the desired spraying effect. In order to obtain high quality anti-static liquid spraying effect, it is necessary to ensure the stability of ultrasonic atomization spraying foggy cone. For this reason, Chi-flying ultrasonic is used to analyze the distribution of carrier gas flow field on the basis of self-designed ultrasonic spray nozzle. The results show that the anti – static liquid spraying effect is achieved by spraying test, and the anti – static effect of the anti – static powder is verified by the spraying test. Liquid savings.

Ultrasonic Atomizer Spraying Video

Standard Unit Spraying Solutions

Standard – Ultrasonic Nozzle

Standard – Ultrasonic Generators

Automatic-Production Spraying Solutions

Flat Type Ultrasonic Spraying Machine

Automatic – UAM3000 Ultrasonic Spraying Machine

Automatic – UAM4000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine